CONSISTENT.

RELIABLE.

TRUSTED.

Celebrating 75 Years!

YOU NEED HIGH-QUALITY

MACHINED PARTS

DELIVERED ON TIME, FROM

PROTOTYPING TO HIGH-VOLUME.

THAT'S WHAT WE DO.

SETTING THE

STANDARD IN

QUALITY

FAST

RESPONSE.

CONSISTENT

DELIVERY.

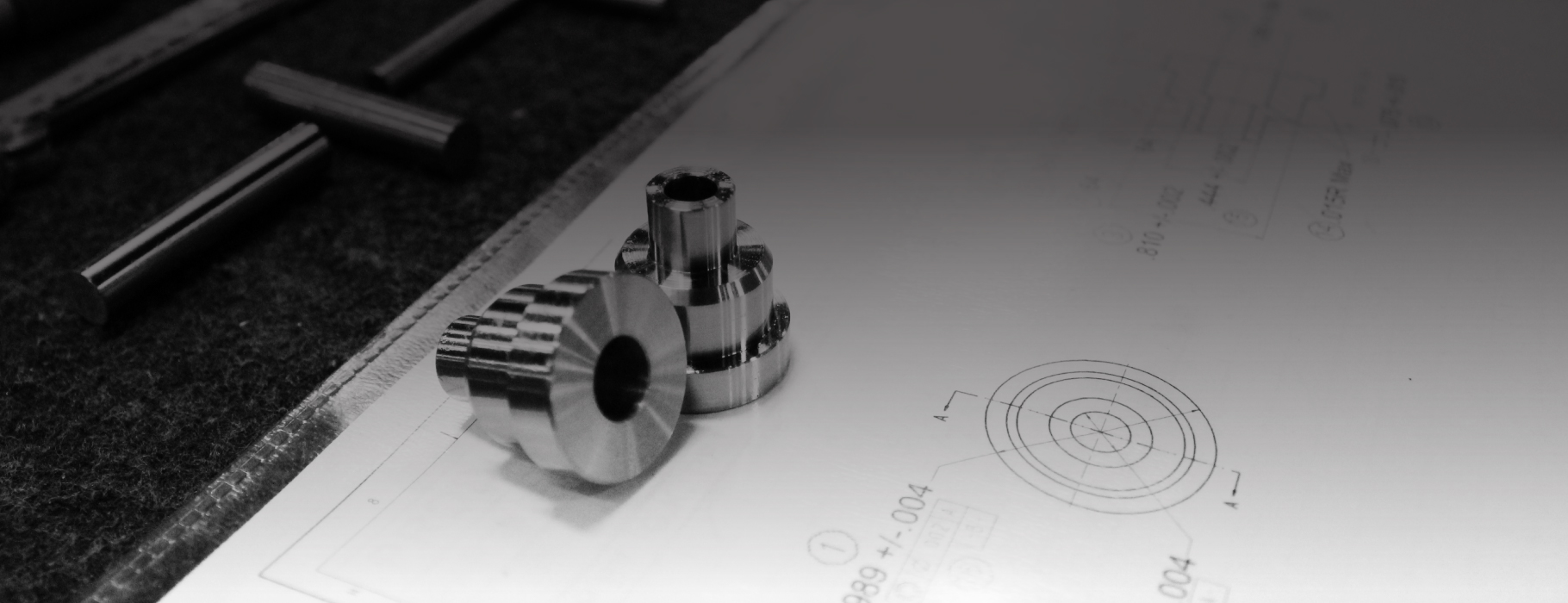

FAST PROTOTYPING

VIA INTERNAL CUSTOM

TOOLING CAPABILITIES

Swiss Machining

Recent investments in Swiss machines have expanded our range of multi-axis, multi-spindle CNC machining capabilities for completing complex parts efficiently in one operation.

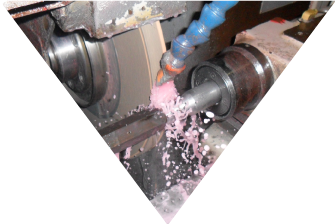

CNC Machining

Cass Precision Machining maintains 30 CNC machines including lathes, mills and turning centers, some of which are equipped with automatic pallet changers and robotic loaders. We machine from bar stock, plate or metal and utilize as many as 11 axes of motion on some of these machines.

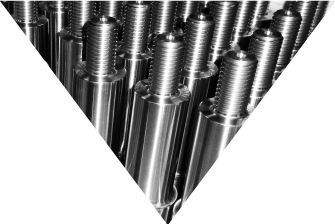

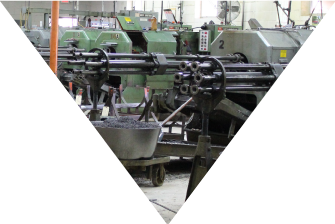

Screw Machining

Screw machining is where it all started at Cass Precision Machining. Two of our five buildings house screw machines, including 43 New Britain automatic multiple-spindle for higher volume orders and 17 Brown & Sharpe single-spindle machines—most of which are equipped with bar feeds—for lower volume orders.

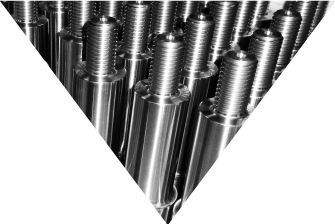

Finish Grinding

Twelve grinding machines—capable of Cylindrical, Centerless or Infeed style grinding—eliminate the need to send your parts out for grinding operations and shorten delivery lead times. We use CNC controls and/or auto-loaders to efficiently handle high-quantity orders.

Swiss Machining

Recent investments in Swiss machines have expanded our range of multi-axis, multi-spindle CNC machining capabilities for completing complex parts efficiently in one operation.

CNC Machining

Cass Precision Machining maintains 30 CNC machines including lathes, mills and turning centers, some of which are equipped with automatic pallet changers and robotic loaders. We machine from bar stock, plate or metal and utilize as many as 11 axes of motion on some of these machines.

Screw Machining

Screw machining is where it all started at Cass Precision Machining. Two of our five buildings house screw machines, including 43 New Britain automatic multiple-spindle for higher volume orders and 17 Brown & Sharpe single-spindle machines—most of which are equipped with bar feeds—for lower volume orders.

Finish Grinding

Twelve grinding machines—capable of Cylindrical, Centerless or Infeed style grinding—eliminate the need to send your parts out for grinding operations and shorten delivery lead times. We use CNC controls and/or auto-loaders to efficiently handle high-quantity orders.

CONSISTENT. RELIABLE. TRUSTED.

That’s a statement that sets a pretty high standard, but it is what drives us.

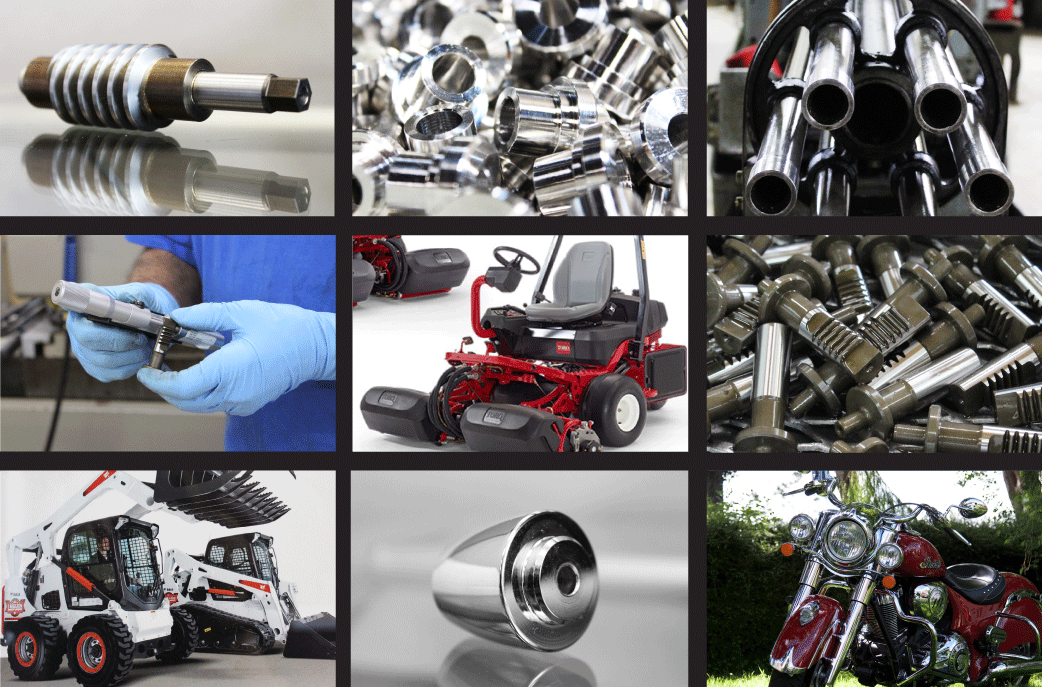

You need high-quality machined parts delivered on time, from prototyping to high-volume industrial manufacturing. That’s what we do.

Founded in 1945, Cass Precision Machining serves you from a five-building campus—including over 125,000 square feet of production space—located in Brooklyn Center, Minnesota. We’re experts in Swiss Machining, CNC Machining, Screw Machining and Finish Grinding. Over the years we’ve worked with many types of materials including steel, aluminum, brass, bronze, tubing and a wide variety of machinable plastics. We provide you with “complete parts” by adding coordinated services such as anodizing, heat treating, light assembly, warehousing and custom packaging. Our quality system guarantees that we will meet your finished part quality specifications on every order.

- Superior Service

- Quality Assurance

- Shipping & Storage

Our customers tell us they are thrilled with our ability to ship on time – every time. Quick responses to quote requests are a priority for us. From prototype through high-volume production run orders, for both custom and industrial manufacturing, we make sure we acknowledge every order we receive so you know in advance what you can expect from our team. In addition, our DFM (Design for Manufacturability) resources are available to help you review and optimize the total costs of your parts. Changes happen, but you can be confident we will support your needs and minimize the hassles. We can make sure that changes in your part design or delivery requirements are quickly deployed into manufacturing so you don’t skip a beat. You can count on us to be there for you for the long haul. Consistent. Reliable. Trusted.

Cass has developed a baseline quality assurance system that guarantees we will ship high-quality parts – on every order. Everything we make passes several in-process checks and a final inspection, or it won’t go out the door. When your requirements dictate, we can customize our baseline system to your specifications, tailoring our quality-assurance system to fit your business needs. We are experienced with quality-assurance tools—SPC, PPAP Cpk, 1st Articles and more—to help you get exactly the results you require in your precision machined parts. Come visit us and check out our systems. We think you’ll like what you see.

To sustain our ability to ship on time – every time, we recently completed a 26,000 sq. ft. expansion to our warehousing, shipping and receiving areas. The added space dramatically improves material flow within our campus and improves efficiencies in our shipping and receiving functions. With the larger warehouse we are able to provide inventory release management programs, which improves the production flow of your lines while allowing us to run optimized quantities under blanket orders for both custom and industrial manufacturing. Consistent. Reliable. Trusted.

HOW CAN WE FULFILL YOUR SPECIFIC NEEDS? CONTACT CASS

Our customers tell us they are thrilled with our ability to ship on time – every time. Quick responses to quote requests are a priority for us. From prototype through high-volume production run orders, for both custom and industrial manufacturing, we make sure we acknowledge every order we receive so you know in advance what you can expect from our team. In addition, our DFM (Design for Manufacturability) resources are available to help you review and optimize the total costs of your parts. Changes happen, but you can be confident we will support your needs and minimize the hassles. We can make sure that changes in your part design or delivery requirements are quickly deployed into manufacturing so you don’t skip a beat. You can count on us to be there for you for the long haul. Consistent. Reliable. Trusted.

Cass has developed a baseline quality assurance system that guarantees we will ship high-quality parts – on every order. Everything we make passes several in-process checks and a final inspection, or it won’t go out the door. When your requirements dictate, we can customize our baseline system to your specifications, tailoring our quality-assurance system to fit your business needs. We are experienced with quality-assurance tools—SPC, PPAP Cpk, 1st Articles and more—to help you get exactly the results you require in your precision machined parts. Come visit us and check out our systems. We think you’ll like what you see.

To sustain our ability to ship on time – every time, we recently completed a 26,000 sq. ft. expansion to our warehousing, shipping and receiving areas. The added space dramatically improves material flow within our campus and improves efficiencies in our shipping and receiving functions. With the larger warehouse we are able to provide inventory release management programs, which improves the production flow of your lines while allowing us to run optimized quantities under blanket orders for both custom and industrial manufacturing. Consistent. Reliable. Trusted.

HOW CAN WE FULFILL YOUR SPECIFIC NEEDS? CONTACT CASS

INVESTMENT LEADS TO THE BEST PRODUCTS

We have customers that have been with us for over half a century. These relationships are earned every day by Cass continually investing in our employees, new technology, and efficiency improvements to offer you the best solutions at competitive pricing.

SETTING THE STANDARD IN QUALITY

Cass has developed a proven quality system based on the year-over-year best-in-quality awards that we are humbled and honored to receive from our customers. We can seamlessly add to our baseline quality system to meet your specifications, tailoring a quality-assurance system to your business needs – on every order we run for you. Everything we make passes several inspections, or it won’t go out the door. We hold monthly quality reviews to assess our performance and results. If a part isn’t right, we fix it.

Client Testimonials

MOTOR SPORTS

“At Arctic Cat we refer to Cass as our ‘rock-star’ supplier. We’ve worked with them for…”

CLIENT TESTIMONIALS

AGRICULTURE

“Cass is very responsive. I send quite a few requests for quotes on a monthly basis… ”

CONSTRUCTION

“At UniPunch Products Inc., we consider Cass as one of our stellar suppliers for some…”

CASS GIVING BACK TO THE COMMUNITY

Cass donated 3,010 pounds of food + $5,018 in cash to the NEAR (North-Suburban Emergency Assistance Response) Food Shelf on 11/28/2023 as part of the Cass Annual Food Drive.